Challenges associated with protective coatings inspections include defects or failures in coating systems due to improper surface preparation, cleanliness, and environmental condition applications. It is essential to verify the quality of coating procedures to prevent unnecessary problems. These challenges can cause delays in the construction schedule, which as a result, will increase the costs of the project. EX.T.IN. SRL has the ability to provide protective coatings inspection services, whether it is to assure surface application methods, required thicknesses, and/or preparation methods.

What is Protective Coatings Inspection?

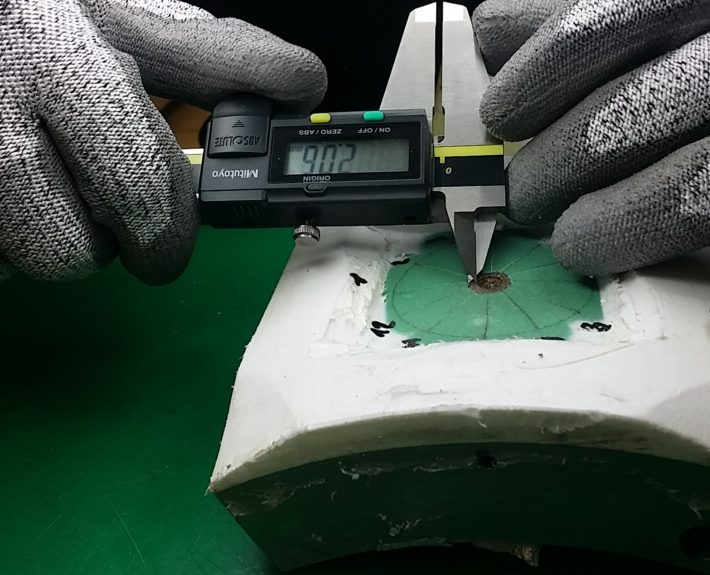

The surface preparation and application of a protective coatings system is the foundation for a successful long lasting coating system. Many factors should be considered when designing a coating application including but not limited to environment, expected service life and application limitations. Good execution of the preparation / application process is necessary to maintain a low annual cost. Also, our NACE Certified Inspectors can be present to witness and perform inspection on coatings and during application in accordance to Specifications and manufacture requirements.

What are the key benefits?

EX.T.IN. SRL provides cost effective solutions in the protection and aesthetics of products while increasing maximum service life. Furthermore, EX.T.IN. SRL provides companies with NACE or FROSIO Certified Inspectors that can be present to witness and perform visual inspections of coatings in accordance to Specifications and manufacturer requirements.

Our inspectors have experience with shop coating, metalizing, epoxy coating, coated rebar and galvanizing. EX.T.IN. SRL can provide full-time NACE/FROSIO Certified Inspectors (I, II and III Levels) as Quality Assurance personnel and Protective Coatings Specialists to perform these services.